Extrusion equipment

Extrusion equipment  Precision processing equipment…

Precision processing equipment…  Stamping equipment

Stamping equipment  Surface Treatment Equipment

Surface Treatment Equipment  Testing equipment

Testing equipment

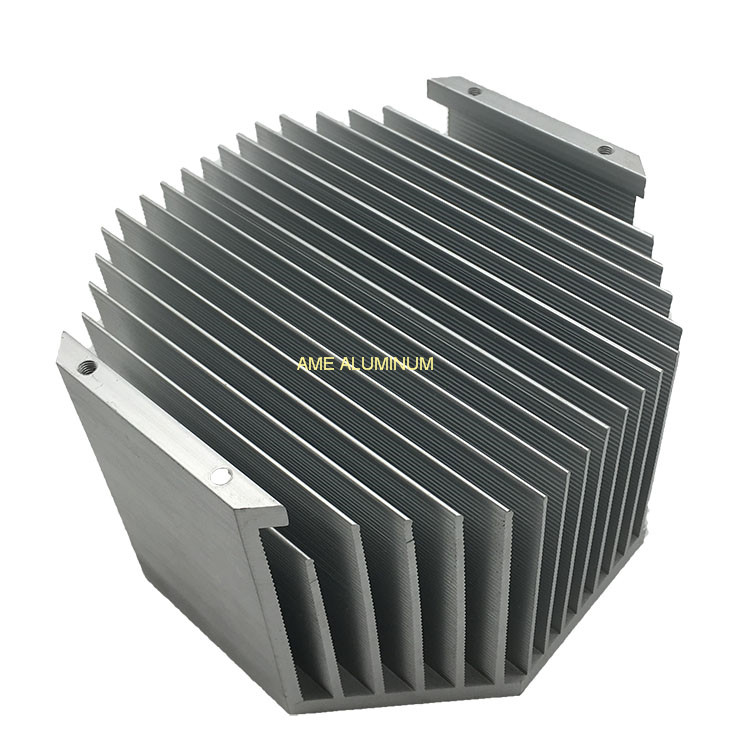

Suzhou AME Aluminum Products Co., Ltd.was born in 2008 and is located in Weitang Town, Xiangcheng District, the hometown of Chinese pearls. The company has been established for more than 12 years and has more than 100 employees. The company covers an area of more than 4,000 square meters. The company integrates aluminum alloy profile product design and development, aluminum profile mold design and manufacturing, CNC processing and sales as an integrated manufacturer. The company’s main technical characteristics are as follows: 1. Production and processing of LED lamp heat sinks; 2. High difficulty radiators, high Difficult aluminum profile mold design, production, and processing; third, large section radiator, large section aluminum profile mold production and processing; fourth, in order to enhance the competitiveness of products, the company has the ability to develop, communicate and cooperate with customers.